IF IT AIN'T BROKE...

don't replace it!

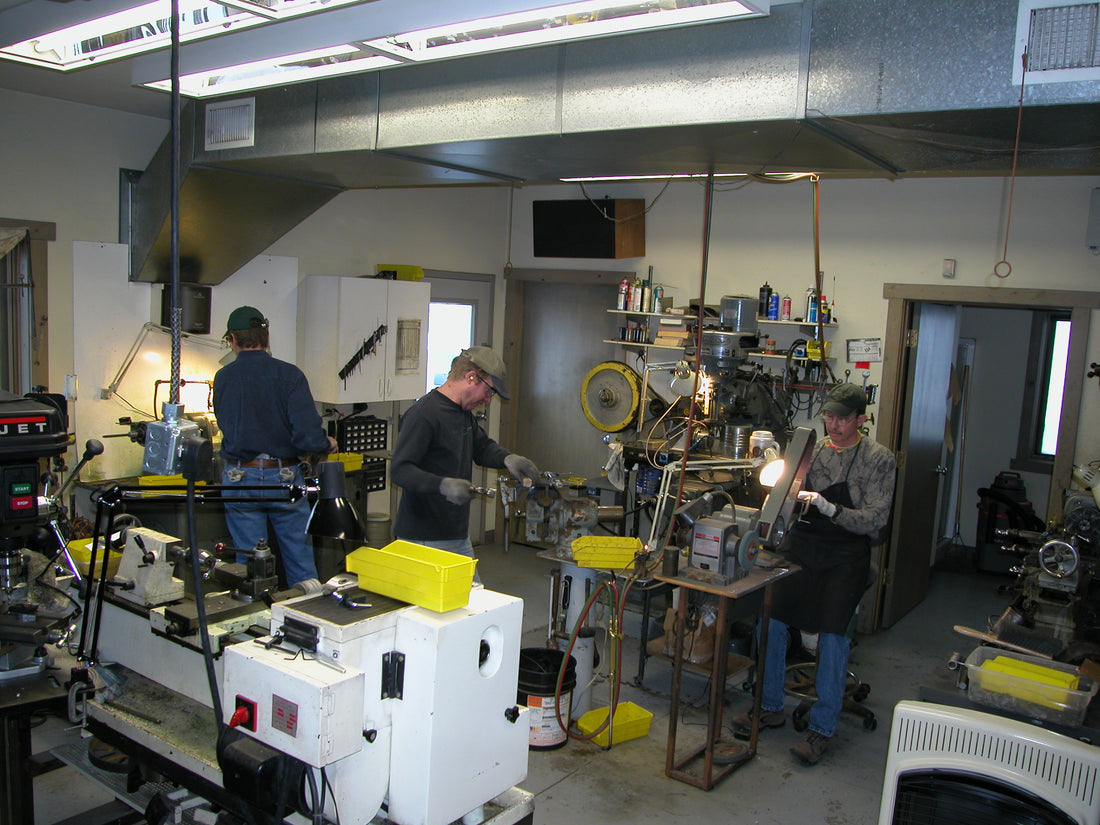

Each bit and spur is hand build through the initial machining down to the hand engraved initials. Through the years Tom has acquired many pieces of equipment to help make the bit and spur building process more efficient - for bending, drilling, and cutting the raw metal. Each piece of equipment has lived a little life before making it to our shop, and is put through rigorous use as it is manned by Tom, Sam, Justin, and Ryan. Here you can see a glimpse of the larger machines in the main fabrication room. This is where the the stock material coming in starts to take shape as a bit or spur.

There are exceptions - machines that were purchased new. Toms welder, bought in 1973 to start his welding business, was one of those items. It finally broke down and repair is not possible. It was a bittersweet parting for Tom. He bought the helmet the same day, but it still has a lot of miles left on it.

New equipment is also brought in if the technology is able to add value to you, our customers. An example of this is our updated grinders for rounding the sharp metal edges on your bits and spurs. We are always working on quality; process through finished product. If you come through the shop for a tour chances are very high that you will see one or more of these mechanical work horses being put to use. It is truly a sight to see. We hope to see you soon!

1 comment

dsd